Monitor Processes

Continuous and real-time measurements to support process development and operations

We provide an excellent way to detect and develop elements of the process. Obtaining first-hand information about the changes in measurements while conducting process changes gives great feedback options for process monitoring. Continuous measuring or single operations, we offer them both always based on your needs.

We have the expertise needed to propose the most suitable method for obtaining valuable results to understand process variables. Depending on the process, monitoring can be done continuously over a longer period, or by means of recurrent measurements following operational activities. Gathered measurement data is followed in real-time in both cases and additional analysis, such as quantifying single sources, is available alongside the reporting.

Single measurements provide targeted snapshots and entail studying emissions under changing conditions or process phases. Measuring is scheduled to take place when a specific process phase or environmental condition is occurring. By measuring recurrently under differing conditions, we are able to improve your understanding of their immediate effect on the emissions and their severity.

Longer term measurements are performed with a semi-fixed device setup. Data gathered over an extended period provide the clearest image of how changes in process variables or environmental factors affect airborne emissions, or can be used to monitor sporadically emitting sources.

Reference: Examples of process monitoring campaigns provided by us: flaring efficiency, fuel tank refills, wastewater treatment process modifications, raw material modifications in process, etc. Wastewater treatment

Flare Measurements

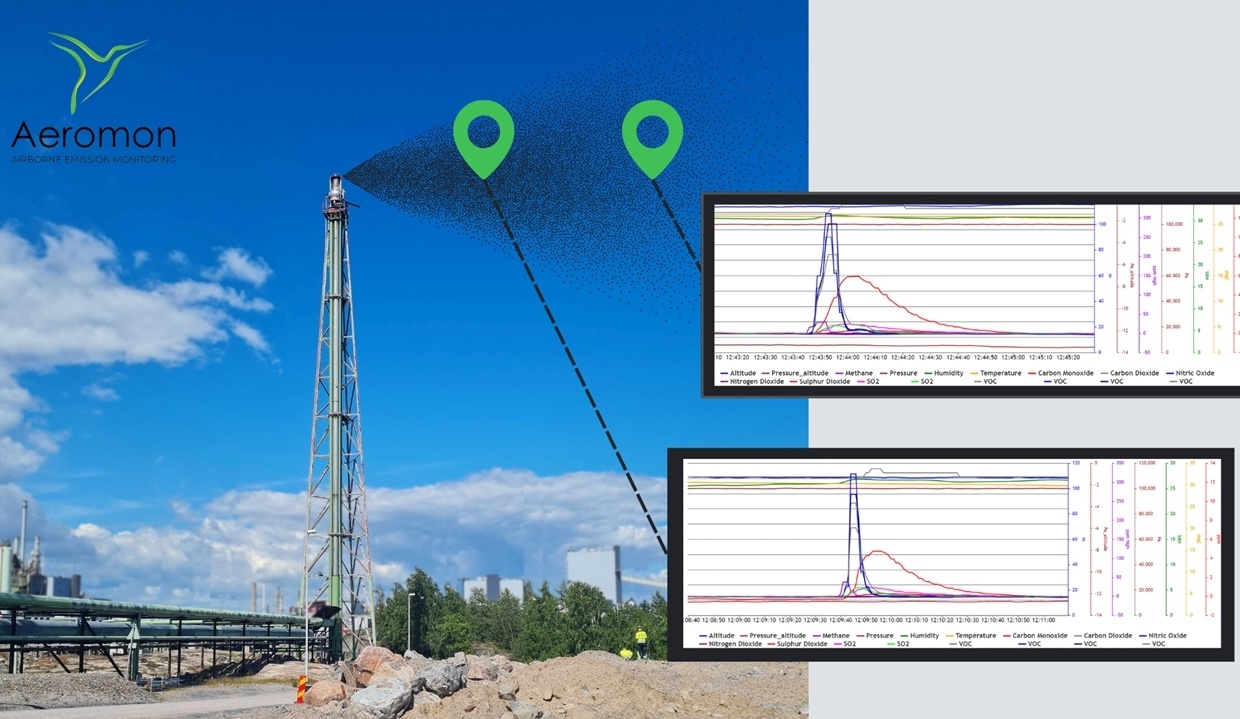

With Aeromon’s UAV-assisted emission monitoring services, companies gain access to real-time insights into flaring operations. Aeromon utilizes advanced sensor technologies to provide precise and comprehensive measurements of flaring activities. From quantifying methane slip to analyzing combustion efficiency, we deliver accurate data, enabling informed decision making and targeted optimization strategies.

Destruction Efficiency (D.R.E)

Quantifying unburnt Methane emissions and correlating this data with the mass flow of methane input to the flare.

Combustion Efficiency

Includes simultaneous measurement and analysis of the concentrations of flaring emissions such as Methane, Carbon Dioxide, Carbon Monoxide, Volatile Organic Compounds and even NOx emissions.