Vopak tank terminals measure the chemical quality and concentrations in the air with Aeromon

Vopak Terminal Vlissingen and Europoort tested airborne emissions from their storage tanks using

Aeromon’s solutions.

“We used Aeromon’s solutions because it can predict concentrations in the air, and it gives us an indication

of the fugitive emissions as well as the individual chemicals that are emitted. That is an advantage above

other methods,” according to Willem van der Zon, Environmental Advisor of Royal Vopak.

Vopak is a multinational independent tank storage company, storing and handling products ranging from

oils, gases, and liquefied natural gas to biofuels and vegetable oils. The company is developing new

infrastructure solutions to actively contribute to the introduction of vital future products, focusing on zeroand low-carbon hydrogen, ammonia, CO2, sustainable feedstock, and long-duration energy storage.

Reducing the impact of chemicals

The company’s goal is not only to reduce the absolute emissions (tons) but

also to mitigate the environmental and societal impact of these emissions.

Moreover, information about the locations of major emission points aids in the

scheduling of maintenance work, thus reducing emissions as swiftly as

possible.

“Some chemicals can have a higher impact than others; therefore, we can

prioritise our efforts to reduce the emissions of the chemicals that have the

highest impact,” van der Zon explains.

Ensuring more efficient maintenance

Aeromon’s analysis increases the speed and effectiveness of maintenance work.

“We could measure a complete area of one of our locations within a day. And we can get the analysis for

every square metre. So, we know exactly what and where we have fugitive emissions. Therefore, we can

direct our maintenance efforts to a specific spot, without climbing up every tank to measure. So, the time

and effectiveness of the maintenance is a huge advantage.”

Improving workplace safety

Further, from a safety perspective, flying above ground level is much safer

than climbing up large tanks (30 to 40 metres high) and walking around.

However, safety involves more than merely avoiding falling; constant exposure

to certain chemicals can also pose an advanced risk.

“When we can do the measurements remotely, we don’t have to be there

ourselves, so we cannot be exposed. Safety is our first priority,” van der Zon

emphasises.

Other calculations can be validated

Aeromon’s solutions also provide an opportunity to validate other calculations.

“Validating calculations is useful not only for ourselves, but we can also show

authorities that our calculations are valid and, thus, reliable,” according to van

der Zon.

MAIN ADVANTAGES

- Real-time and visualised emission data

- Improved maintenance prioritisation and planning

- Reduced product loss and air pollution

- Support to process development & optimisation

- Enables data-driven decision making

Detecting VOCs

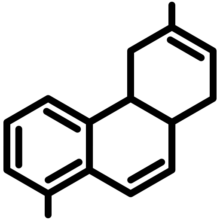

Vopak Vlissingen uses drones equipped with detectors for volatile organic compounds (VOCs).

“VOCs are molecules that evaporate into the atmosphere and not into the layer where they would be

speeding up the climate change. But from the atmosphere, they will come back to Earth and have a

harmful impact. That’s why they are included in the impact model of our emissions,” van der Zon explains.

“We have been measuring several chemicals from propane (C₃H₈) to benzene (C6H6) and other

petrochemicals.”

“We are very satisfied with Aeromon’s approach and satisfied with how they present the data.”

Vopak invests in Aeromon

Vopak has also invested in Aeromon via its venture arm, Vopak Ventures.

“The activities of Aeromon very well match with the ambition of Vopak Venture’s sustainability fund in

which we identify investment opportunities in start-ups and scale-ups in new technologies to make the

industry more sustainable,” according to Leo Brand, CIO of Royal Vopak and Chairman of Vopak Ventures.

Aeromon’s services are used by companies throughout Europe to verify and quantify emissions from

industrial plants. Their modular unmanned aerial vehicle (UAV)-assisted emission monitoring solutions

have proven to create value in complex and demanding environments within, for example, the oil and gas,

chemical, waste management, energy, and mining industries.