Other Sectors

We will customise our measurement services to best suit your line of work and offer reporting that is of most value to you.

With extensive experience in various sectors, we have a proven track record of providing high quality information on airborne emissions to customers. With the ability to measure up to 20 parameters simultaneously, we are able to provide holistic real time information on fugitive emissions.

As more sectors become aware of their environmental footprint, our technology provides you with a versatile means of understanding your airborne emissions. We measure a wide variety of parameters ranging from gaseous compounds to particulate matter and noise. Our findings are given to you in an easy-to-understand, visualised format, that can be used for informing future actions.

Our BH-12 modular measurement device has proven itself to be a powerful tool for monitoring previously inaccessible locations. The BH-12 adapts well to challenging field operation conditions and is often assisted by an unmanned aerial vehicle (UAV) but can be used with other means of mobile device installations or as a handheld device. The measurement methods we utilise are chosen based on your needs and site-specific features.

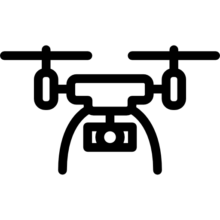

Our Area Mapping technique produces site level data in a systematic and repeatable way. Area mappings are valid at any point in the lifecycle of the site. In particular, pinpointed sources are inspected individually in greater detail to provide more specific information, such as concentration levels and quantities.

By utilising our fenceline method, we measure the dilution and spread of emissions at multiple altitudes and distances from a point or area source. The resulting 3D emission data gives you unprecedented insight into how harmful emission concentrations disperse.

After analysis the data we obtain is presented in an easy-to-understand heat map that is overlaid on top of a satellite image and infrastructure map if provided. These maps, known as choropleth maps, efficiently give a comprehensive view of the whole site with pinpointed sources. The information we obtain on fugitive emissions aids you in meeting existing and upcoming sustainability goals and regulatory requirements.

Pulp & Paper

Extensive emission monitoring with a quick response time to hasten the solving of odorous production hurdles and mitigate overall emissions

Ability to measure multiple gaseous compounds simulaneously allowes us to provide holistic information on airborne emissions from the production process, as well as sources and the spread of emissions. Our measurements have proven to create value with customers such as Stora Enso and UPM.

Accurate, real-time data on emissions is valuable to employee safety, development and maintenance planning, as well as for environmental reasons. We can support your operations with site-level information, thereby improving your awareness of the effect a specific plant has on the surrounding air and how different processes contribute to overall emissions.

We can efficiently monitor odorous fugitive emissions and leaks from the pulp and paper production process. This is due to our ability to simultaneously measure up to 20 gaseous components, in addition to particulate matter and noise, in real time. Our UAV-assisted emission mapping services are a flexible way of understanding where problematic sources are located, whilst our emission fenceline measurements can further monitor spread and dilution from the site. We are also capable of easily performing longer-term measurements of specific sources to support process development.

Mining & Steel

Measuring noise in previously inaccessible locations along with dust and other emissions to further study current production processes.

The environmental impact of industrial sites on surrounding areas is challenging to document. We provide the best solution available for monitoring noise and dust dispersion. By performing continuous real time measurements, we are able to examine the contributions of different processes and how process variables affect emissions.

Fugitive emissions occur at every stage of mining and steel manufacturing and is a common challenge faced in this sector. Understanding their sources and the severity of their impact to surrounding areas has been difficult to measure using traditional methods. Our services adapt well to challenging field operation conditions and are often assisted by an unmanned aerial vehicle (UAV) but can be used with other means of mobile device installations or as a handheld device.

Recycling & Waste Management

Measuring landfill gases for maintenance and environmental reporting to facilitate a decrease in greenhouse gases and odorous compounds.

With our UAV-assisted emission measurements, we are able to provide information on surface emissions, the efficiency of the gas collection network and possible odorous spreading from the site. A comprehensive overview of the area’s emission sources allows maintenance work to be targeted on key locations followed by visualized results of your emission reduction.

Waste management facilities must be regularly inspected and kept in good condition to maintain safe operations on site and avoid harming the environment. Whilst target compounds are always based on your needs, primary gases in waste management emission measurements often include

- methane

- carbon dioxide

- hydrogen sulphide

- nitrous oxide

- volatile organic compounds

Maritime sector

In maritime applications Aeromon’s technology provides authority-approved ship sulphur emissions monitoring. Our platform has been used in European territorial waters for both sulphur and methane slip measuring. Today, maritime measurements are conducted by a joint venture company NUAER.

Services

The SCIPPER Project

Aeromon is a proud partner of project SCIPPER which is funded by EU's H2020 reserach and innovation programme. SCIPPER aims at deploying state-of-art and next-generation measurement techniques to monitor emissions of vessels under their normal operation.

Aeromon Service Process

Planning

The measurements are planned and reviewed with the client to ensure the best possible outcome. Measurement plan can be reviewed by needed interest groups before purchasing decision and updated by Aeromon when needed. Aeromon will provide a site specific risk analysis and permits for flying.

Measurements

Aeromon will conduct measurements according to plan adapting to possible changes / new points of interest during the day. Preliminary results are gone through with the customer and further measurements can be conducted in customer’s areas of interest to locate emission sources.

Reporting

A thorough report in pdf-format is delivered shortly after the campaign. Report will be gone through with an Aeromon specialist in an online meeting (Teams). Next steps and further measurements are discussed to validate future development, maintenance work etc.

Aeromon Service Model

Initial measurements

Providing holistic emission data to support investment decisions, maintenance operations etc. Understanding the site and processes to propose further co-operation to serve the purposes and needs of the customer

Recurring Measurements

Validating results of maintenance operations. Seasonal measurements to understand various processes and weather-related effects better. Emergency measurements, ie. Odorous issues and leak detection in short response time

Long-term Monitoring

Gathering information about production processes continuously in real time with a rental BH-12 device through Aeromon Cloud Service. Reports are created by Aeromon with agreed intervals

Contact our experts!